Steel Manufacturing Simulation & Visualization Consortium

The Cutting-edge Industry-led Consortium for Modeling, Simulation, and Visualization of Iron and Steelmaking is housed at Purdue University Northwest’s Center for Innovation through Visualization and Simulation (CIVS).

About SMSVC & CIVS

The Steel Manufacturing Simulation and Visualization Consortium (SMSVC) is a nationwide, industry-led sustainable consortium launched in 2016 by the Center for Innovation through Visualization and Simulation (CIVS) at Purdue University Northwest, and is supported by more than 16 companies and organizations.

The Consortium

Through the support of a National Institute of Standards and Technology (NIST) AMTech Planning Grant, this consortium was founded to be an industry-led sustainable steel consortium focused on supporting the development and implementation of simulation and visualization technologies/techniques.

Learn More about the Consortium Mission and Research Areas →

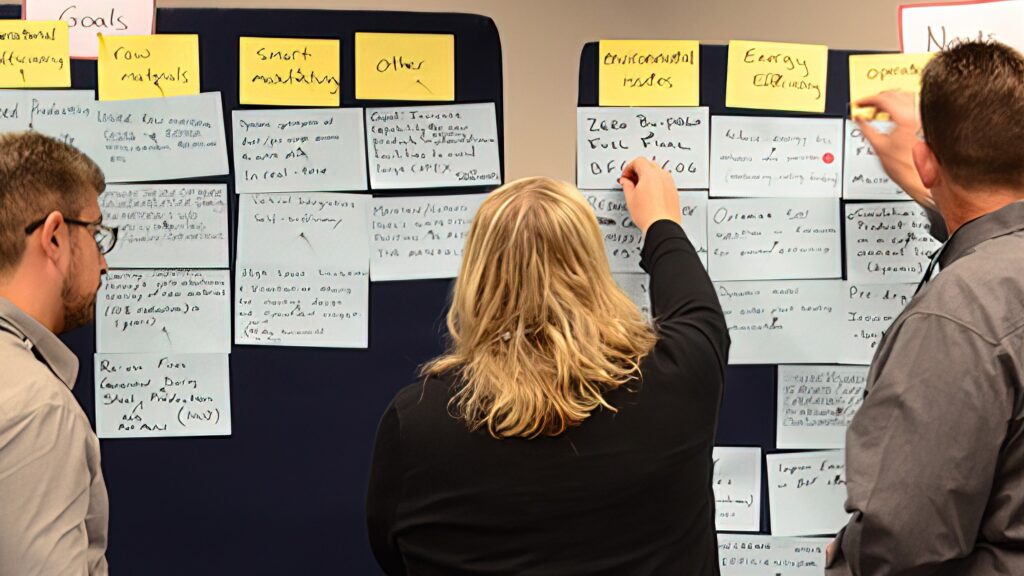

Roadmaps

Through the support of the National Institute of Standards and Technology (NIST), workshops were held to help identify and help guide long-term pre-competitive research areas relevant to advancing U.S. steel manufacturing competitiveness across the entire steel industry.

Project Showcase

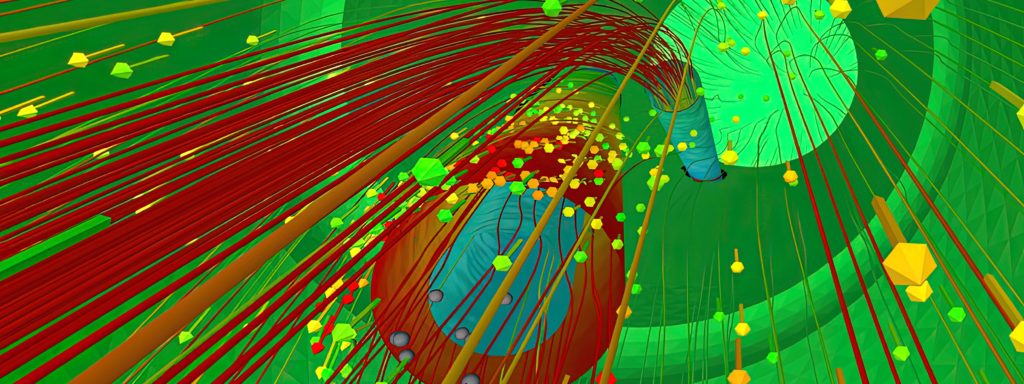

Innovation, Application, and Education:

Numerical simulations and virtual/visual representations are being increasingly used for research and process improvement. Such simulations and visualization can provide fundamental insights of complex phenomena and practical foresights for process and product design, optimization, scale-up, and troubleshooting. Integration of visualization technologies in other areas like workforce development can also provide several different kinds of cost-effective and scalable solutions.

Get Involved

Discover New Ways to Solve Problems:

In many fields and for many processes, CIVS and the SMSVC’s advanced simulation and visualization technologies have proven to be invaluable for designing, troubleshooting, and optimizing processes and products which reduce both time and cost…

Discover New Approaches to Training:

The integration of simulation and visualization technologies also opens up new avenues for training and learning. In CIVS’s 3-D Immersive Theater or using VR technology, we can “fly” into a virtual processes and observe phenomena impossible to view in the real world…

Mission & Vision

“Our mission is to develop and implement innovative technical solutions through the integration of advanced computer simulation and visualization technologies for the value chain of U.S. Steel Manufacturing”

“Our vision is to be the institute of choice for developing and applying advanced computer simulation and visualization technologies to ensure a competitive advantage for U.S. Steel Manufacturing.”

Core Values

“Integrity, effectiveness, practical application, and people.”